Know More About

Deck Forming

Reliable and Efficient Deck Forming Solutions

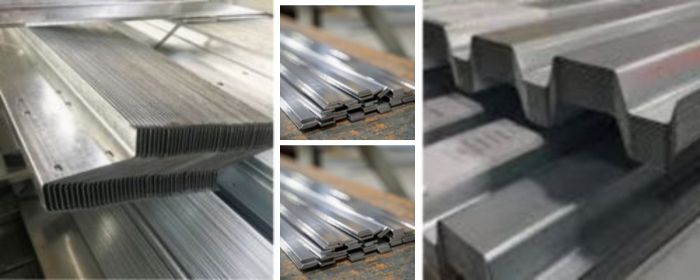

Our Deck Forming Solutions

Explore our high-quality deck forming systems, engineered to deliver exceptional performance and durability for modern construction projects. Our deck forming sheets are designed to act as permanent formwork for concrete slabs, combining superior strength, ease of installation, and long-term reliability.

Made from premium-grade steel and precision-manufactured, our deck forming products ensure excellent load-bearing capacity and seamless integration with structural designs. Whether for commercial, industrial, or residential applications, our deck forming solutions provide the perfect balance of functionality and efficiency.

Discover the ideal deck forming products for your construction needs, backed by our unwavering commitment to quality and customer satisfaction.

Key Features and Benefits:

Shaping Strength, Building Tomorrow

Superior Strength and Durability: Manufactured from high-grade steel to ensure excellent load-bearing capacity and structural integrity.

- Ease of Installation: Lightweight design allows for faster and more efficient assembly, reducing labor costs and project timelines.

- Multi-Functional Design: Serves as both a working platform and a permanent formwork, eliminating the need for temporary supports.

- Enhanced Concrete Bonding: Designed with ribbed or profiled surfaces to improve adhesion between the steel deck and concrete.

- Corrosion Resistance: Available with galvanized or coated finishes for extended durability and protection against environmental factors.

- Customizable Sizes and Profiles: Tailored to meet diverse project requirements with a range of thicknesses, lengths, and profiles.

- Cost-Effective Solution: Reduces material wastage and optimizes the overall construction process.

Whether for commercial high-rises, industrial buildings, or residential projects, our deck forming products are designed to meet the highest standards of quality and performance.

Shaping Strength, Building Tomorrow

Forging Excellence as Your Premier Steel Partner

Deck Forming Specifications

Our deck forming sheets are designed to meet the rigorous demands of modern construction, offering durability, precision, and versatility. Below are the key specifications:

Material Composition:

- Made from high-quality galvanized or coated steel for long-lasting performance.

- Conforms to international standards such as ASTM, BS, or EN for quality and safety.

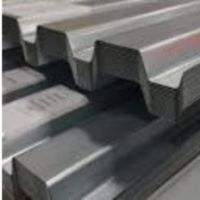

Profile Dimensions:

- Depth: Available in multiple profile depths (e.g., 50 mm, 75 mm, 100 mm) to suit various load requirements.

- Width: Standard and custom widths, typically ranging from 600 mm to 1200 mm.

- Thickness: Steel thickness options ranging from 0.8 mm to 1.5 mm, depending on project needs.

Load-Bearing Capacity:

- Engineered to support heavy loads with exceptional structural integrity.

- Tested for performance under dynamic and static conditions.

Surface Features:

- Ribbed or embossed patterns to ensure superior bonding with concrete.

- Smooth finishes for easy handling and installation.

Coating and Corrosion Resistance:

- Galvanized with a zinc coating thickness of [e.g., 120 GSM to 275 GSM] for corrosion protection.

- Optional pre-painted or zinc-aluminum coatings for enhanced durability.

Length Options:

Khair Steel Industrial Company embraces the latest in manufacturing technology to deliver cutting-edge solutions to our clients. Our operations include:.

Fire and Safety Standards:

Khair Steel Industrial Company embraces the latest in manufacturing technology to deliver cutting-edge solutions to our clients. Our operations include:.

Premium Steel Solutions

Superior Quality

Our products are crafted for strength and precision. From durable pipes to versatile sheets and corrosion-resistant zinc, Khair Steel delivers quality and reliability to meet your needs.

Request a Quote Now!

Take the first step toward excellence!

Partner with us for top-notch steel products tailored to your needs. Don’t wait—let’s build success together!

Slitting Machines

ssdfsdsdfsdfsfsdfsdfs

Purlin Forming

fdbgdfdfgfdgfdg

Deck Forming

rgergegergreg

Cut-to-Length Units

dfbgdfgdgdfg